cad/cam & CAA V5 Based

cad/cam & CAA V5 Based

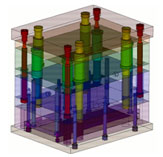

PLM solution of mold & die based on CATIA V5

Gold Software Partner

| Space-E /CAM |

|

|

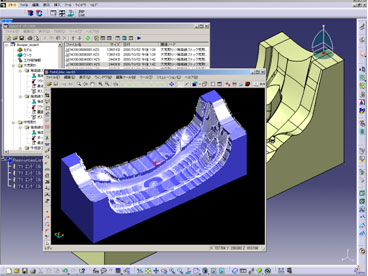

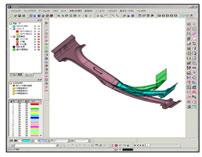

Simple Saving of Machining Processes Traditional labor-consuming path creation is unified into the "Save Machining Process." The Graphical User Interface presents "operations as you see" for even first-time users. Support Tools Space-E provides many support tools including: Simple Path Viewer, Cutting Image View, and CAM Web. CAM Web is unique in that it outputs and an HTML-based text file containing all Information of a model and the NC data Fast, Accurate, and Productive Machining Included are rich sets of cutting know how developed by NDES over its many years of leadership in the Japanese CAM market. These include: state-of-the-art NURBS interpolated NC, contour based high speed cutting, trochoid cutting, thrust cutting and much more. |

|

2.5 CAM Provides many easy-to-use CAM functions such as pocketing, profile cutting and drilling. Automation and Standardization of Cutting

You can make your cutting procedures developed over the years as your standard mode of operation. With its standardized and automatic operations, Space-E allows first time users to cut precise models. |

Space-E / Modeler |

|

|

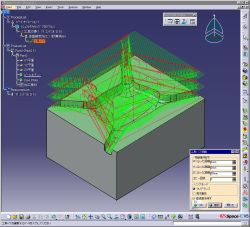

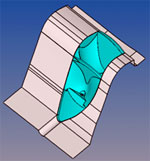

Hybrid Surface/Solid Modeling Support of 2D Drawings You can easily layout projections or section drawings of surface-solid mixed data. Removing hidden lines or dotted line displays are handled automatically. You can export your 2D layout data to other 2D drawing CAD systems in DXF format. |

|

Evaluation of Workability and Moldability This function evaluates undercut taper and fillet. Together with other automatic functions, this makes the assessment of geometry and decision making by die and mold designers much easier . Customized Language FDLI (Feature Design Language Interpreter) |

| Space-E CAA V5 Based |

|

|

|

|